- Thermocouple of the crucible directly in the bath but protected by a special sleeve – T-c connected to the PC

- Thermocouple for the die connected to the PC

- Special injector of gas (Argon or N2) for the internal protection of the crucible

- Special injector of gas (Argon or N2) for the internal protection of the dies

- Die and crucible are externally protected by a special ceramic jacket to avoid a fast downgrading of the graphite from the oxygen.

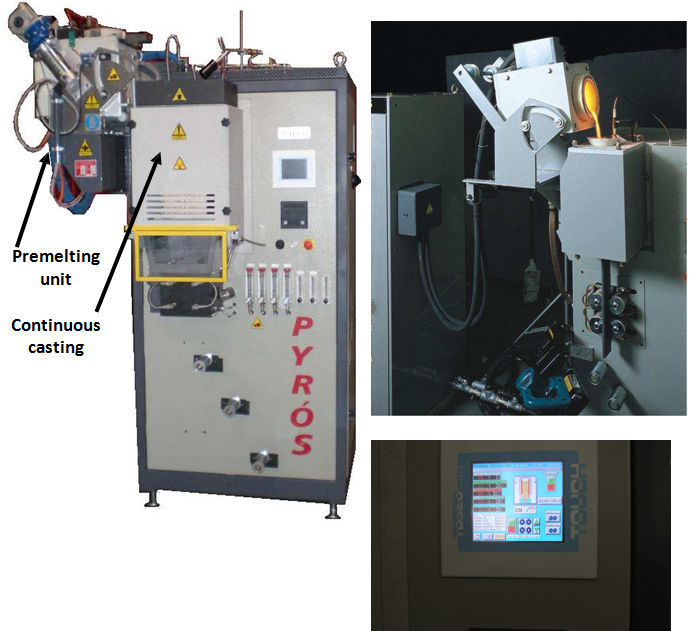

- The furnace is equipped with a Microprocessor with a LCD display having the possibilities to change till 8 different languages

- The furnace is equipped also of a printer integrated in the panel board able to print all the data of working –

- The microprocessor has the possibilities to memorize till 100 different pages containing all the information concerning the material to treat – the working parameter and date.

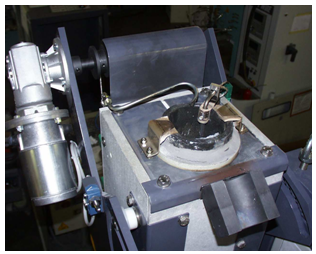

- Furnace will be equipped with automatic shear installed directly on the machine( see the above pic on left side)

- Special mechanical protection system for accidental casting of the metal.

- Double series or rollers cooled down by water circuit

- Special Cooling jacket get from a bronze block special worked that surround perfectly the die to get a better cooling efficiency.

- Possibility to apply for special alloy like white or red gold alloy – a device that cool down quickly the alloy.

- Power supply possible: 220V or 380V 50/60 Hz / 3 Ph

- Power of the furnace: 18 kW

- Working frequency of the converter: ~20 Khz

- Usefull size of the crucible for SILVER: 14,8 Kg (AG925)

- Extraction profiles

- Plate: Max. 100×10 mm

- Tube: Max 40 X 2mm

- Wire: Min. 6 mm – Max. 10 mm

- Max working temperature: 1500° C

- Extraction speed (min-max): 0,05 1,00 m/min

- Die installed: To be specified by the Customer

- Cooling water requirement T° 15 to 30°c: Pressure 2 – 3 bar

- Water consumption: 20-30 l/min

- Gas for protection: Nitrogen or argon

- Gas consumption (pressure from 0,5 – 1 bar): 10-20 l/min;

- Gas for the process ( for special alloy): GPL or Propane gas;

- Gas consumption (pressure from 0,5 – 1 bar): 20 l/min;

- Compressed air pressure required: 4 to 8 bar;

- Aspiration for the Exhaust over the crucible: (minimum speed required) 10m/sec;

- Dimensions (depth x width x height): ~ 2050 x 1400 x 2550 mm.;

- Weight: 725 kg;

- More energetic safe with low losses;

- More silences

- Less encumbrance

- More precision in the power control

- Power supply possible ( to specify during the order):415V 50Hz/three phases;

- Power of the furnace:15 Kw;

- Working frequency of the converter:~20 Khz;

- Useful size of the crucible

- Max working temperature:1500° C;

- Cooling water requirement T° 15 to 30°c:Pressure 2 – 4 bar;

- Water consumption:~ 20 l/min:

- Gas for the process:GPL or Propane gas;

- GPL gas consumption (pressure from 0,03 – 0.05 bar):0,5 m3/h;

- Aspiration for the Exhaust over the crucible:(minimum speed required) 10m/sec;

|

Item |

Description |

Nr. |

TOTAL PRICE (€) |

|

Z50_315Ag + Z52_03

1500°C |

Ieco Continuouscasting capacitykg.15withmax plateproductionup to mm.100.MaxTemp1500°C Automaticpre-melterkg10Agcapacity installedin thecontinuous casting. Equipped with automatic cutting shear installed directly incontinuous casting Settledwithcrucible,die(die’ssizebespecified)andstartingbar. |

01 |

114.000,00 |

|

|

|

|

|

|

|

Extraconsumablesandspareparts |

|

|

|

|

–SparepartsforAgonly |

|

|

|

63500334 |

Cruciblekg.15Ag |

10 |

4.350,00 |

|

66300302 |

Crucible’scover |

05 |

275,50 |

|

64550845 |

Die uo to mm.100 |

10 |

7.650,00 |

|

|

S.S. Startingbar |

02 |

360,00 |

|

61200066 |

Ceramicclayforcrucibleanddie |

10 |

464,40 |

|

|

–SparepartsforAuonly |

|

|

|

………….. |

Cruciblekg.27Au |

10 |

4.350,00 |

|

………….. |

Crucible’scover |

05 |

275,50 |

|

|

Die up to mm.100 |

05 |

3.825,00 |

|

|

S.S. Startingbar |

02 |

360,00 |

|

61200066 |

Ceramicclayforcrucibleanddie |

10 |

464,40 |

|

|

|

|

|

|

|

-General Spareparts |

|

|

|

38610017 |

CrucibleThermocoupleforhigh temperature |

02 |

53,40 |

|

34510015 |

Die Thermocoupleforhigh temperature |

02 |

180,76 |

|

|

Protective materials(forcruciblechanges) |

05 |

1.680,00 |

|

|

Coatingforthermocouples |

20 |

free |

|

|

Spareparts&consumablesforcontinuous casting |

|

24.288,96 |

|

|

|

|

|

|

|

Pre-melter |

|

|

|

|

–ExtraconsumablesforAg |

|

|

|

|

Cruciblekg.10Ag |

10 |

750,00 |

|

|

Graphite rod |

05 |

42,05 |

|

|

|

|

|

|

|

–ExtraconsumablesforAu |

|

|

|

|

Cruciblekg.15Au |

10 |

750,00 |

|

|

Graphite rod |

05 |

42,05 |

|

|

|

|

|

|

|

–Spareparts |

|

|

|

|

Thermocouplesforhigh temperature |

02 |

164,74 |

|

|

Spareparts&consumablesforpre-melter |

|

1.748,85 |