IKOI Density Booster Model Z95-124 to Produce Mechanical Grains

IKOI Density Booster Model Z95-124 to Produce Mechanical Grains

Location:Italy

Description

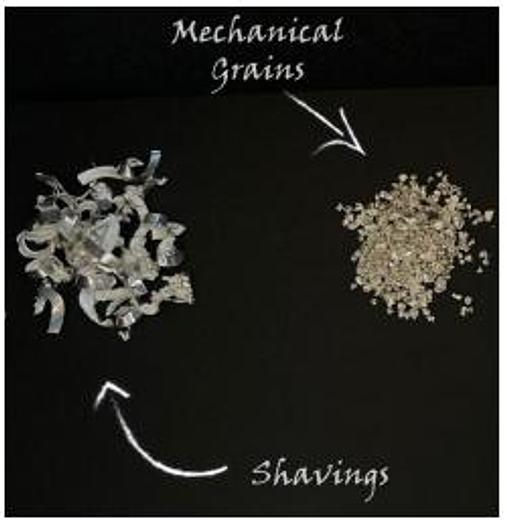

The IKOI Density Booster is the new patented technology from IKOI to create mechanical granules or sand from silver shavings or silver crystals. The mechanical granules and the sand have the same density as silver grains!

The operator will feed the hopper, positioned on the floor close to the Density Booster, with silver crystal. It is important that crystals must be with a moisture less than 1-1,5% and with a minimum specific weight of 2,2 Kg/dmc.

The ground hoper is supplied with an auger for transferring automatically the crystals to the Density Booster. The feeding system is automatic and calibrated for providing a regular quantity of crystal inside the Density Booster insertion vessel located at the entrance of the machine. This device is important to avoid the stockage of the crystal inside the rotating system.

At the exit of the machine the silver crystal is transformed into silver sand with a density almost double the density of the incoming material

With the density booster the shavings from the Ultra Bite® are transformed into mechanical grains. The density booster® is a mechanical processing machine to increase the bulk density of silver shavings and crystals. The equipment is a rotating unit which is capable to compressed the material into spherules. Using this technology, the bulk density increases and the material is easy to handle, weight, dose and load both manually and with automated systems.

Description of the Density Booster:

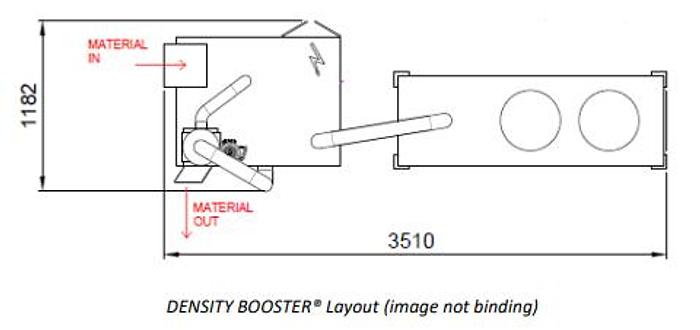

Plant is built from two parts:

- Main machine that does the compression of the material (increasing the material density)

- Bag filter for filtering the air generated by the centrifugal extraction fan

The main machine, that performs the increasing of the material density, consists of:

- Welded stretched, sandblasted painted carpentry structure including basement, equipped with soundproof panels

- Feed funnel for the material to be compressed

- Two-stage compacting rotary element with variable speed

- Material extraction centrifugal fan

- Decanter cyclone with outlet channel for the compacted material

- Rotary valve

- Vacuum pipe from cyclone to centrifugal fan

- Suction pipe from rotary compaction element to the cyclone

- Exhaust pipe to bag filter

- Electrical command and control panel

The bag filter for filtering the air generated by the centrifugal extraction fan consists of:

- Welded, stretched, sandblasted painted carpentry structure including basement

- Two antistatic sleeves

- Pneumatic cleaning of the sleeves

Specifications

| Manufacturer | IKOI |

| Model | Z95-124 |

| Year | 2025 |

| Condition | New |

| Stock Number | 779455 |

| Electrical Requirements | 480 Volts / 3 Phase / 60Hz |

| Installed power | ~15Kw |

| Treatable Metals | Pure silver crystals coming from electrolysis (moisture max 1-1,5%, minimum specific weight 2,2Kg/dmc) |

| Maximum productivity with crystals | ~180-190 Kg/h |

| Bulk density of the “mechanical coarse sand” produced from Ag crystals | ~5,0-5,5 Kg/dm³ |

| Environment temperature (min-max) | ~10-40 °C |

| Max relative moisture | 70% @ 25 Degrees C Amb. |

| Estimated weight | 1,100 Lbs |

| Overall Dimensions | 139" x 47" (LxW) |