New GOLDPRO® IECO CONTINUOUS CASTING MACHINE 15KG – FOR PLATE UP TO 100mm

New GOLDPRO® IECO CONTINUOUS CASTING MACHINE 15KG – FOR PLATE UP TO 100mm

Location:Pawtucket, RI

or

Call 1-800-619-GOLD

Description

TECHNICAL FEATURES

Thermocouple of the crucible directly in the bath but protected by a special sleeve – T-c connected to the PC

Thermocouple for the die connected to the PC

Special injector of gas (Argon or N2) for the internal protection of the crucible

Special injector of gas (Argon or N2) for the internal protection of the dies

Die and crucible are externally protected by a special ceramic jacket to avoid a fast downgrading of the graphite from the oxygen.

The furnace is equipped with a Microprocessor with a LCD display having the possibilities to change till 8 different languages

The furnace is equipped also of a printer integrated in the panel board able to print all the data of working –

The microprocessor has the possibilities to memorize till 100 different pages containing all the information concerning the material to treat – the working parameter and date.

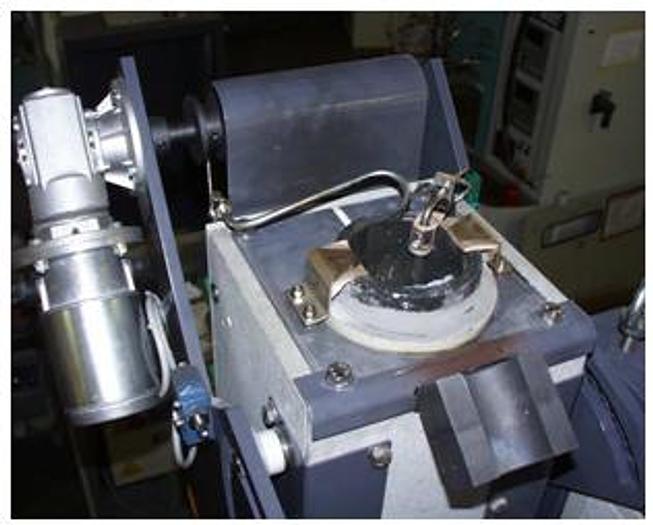

Furnace will be equipped with automatic shear installed directly on the machine( see the above pic on left side)

Special mechanical protection system for accidental casting of the metal.

Double series or rollers cooled down by water circuit

Special Cooling jacket get from a bronze block special worked that surround perfectly the die to get a better cooling efficiency.

Possibility to apply for special alloy like white or red gold alloy – a device that cool down quickly the alloy.

Technical data sheet

Extraction profiles

Aspiration for the Exhaust over the crucible: (minimum speed required) 10m/sec;

Art.Z52-03: Induction melting furnace at medium frequency for the pre-melting of precious-metal alloys in graphite crucible, with automatic temperature control.

Equipped with a special tilting mechanical frame to allow the pre-melted metal contained in the crucible to be poured on a crucible of the continuous casting machines.

The melting head is fixed to the frame of the continuous casting and placed in the way that the pouring will be made through a remote control device.

Equipped of electronic generator of new conception, which allows:

More energetic safe with low losses;

More silences

Less encumbrance

More precision in the power control

Equipped of microprocessor controller with display at liquid crystals for the regulation and the checking of the furnace.

VIEW OF THE TILTING PREMELTING UNIT

Technical data sheet

Useful size of the crucible

Specifications

| Condition | New |

| Z50 315Ag + Z52 03 1500°C | Ieco Continuouscasting capacitykg.15withmax plateproductionup to mm.100.MaxTemp1500°C Automaticpre-melterkg10Agcapacity installedin thecontinuous casting. Equipped with automatic cutting shear installed directly incontinuous casting Settledwithcrucible,die(die’ssizebespecified)andstartingbar. 01 114.000,00 |

| 63500334 | Cruciblekg.15Ag 10 4.350,00 |

| 66300302 | Crucible’scover 05 275,50 |

| 64550845 | Die uo to mm.100 10 7.650,00 |

| 61200066 | Ceramicclayforcrucibleanddie 10 464,40 |

| ………….. | Crucible’scover 05 275,50 |

| 38610017 | CrucibleThermocoupleforhigh temperature 02 53,40 |

| 34510015 | Die Thermocoupleforhigh temperature 02 180,76 |

| Power supply possible | 220V or 380V 50/60 Hz / 3 Ph |

| Power of the furnace | 15 Kw; |

| Working frequency of the converter | ~20 Khz; |

| Usefull size of the crucible for SILVER | 14,8 Kg (AG925) |

| Plate | Max. 100×10 mm |

| Tube | Max 40 X 2mm |

| Wire | Min. 6 mm – Max. 10 mm |

| Max working temperature | 1500° C; |

| Extraction speed (min-max) | 0,05 1,00 m/min |

| Die installed | To be specified by the Customer |

| Cooling water requirement T° 15 to 30°c | Pressure 2 – 4 bar; |

| Water consumption | ~ 20 l/min |

| Gas for protection | Nitrogen or argon |

| Gas consumption (pressure from 0,5 – 1 bar) | 20 l/min; |

| Gas for the process ( for special alloy) | GPL or Propane gas; |

| Compressed air pressure required | 4 to 8 bar; |

| Dimensions (depth x width x height) | ~ 2050 x 1400 x 2550 mm.; |

| Weight | 725 kg; |

| Power supply possible ( to specify during the order) | 415V 50Hz/three phases; |

| Gas for the process | GPL or Propane gas; |

| GPL gas consumption (pressure from 0,03 – 0.05 bar) | 0,5 m3/h; |

| Aspiration for the Exhaust over the crucible | (minimum speed required) 10m/sec; |

| Item | Description Nr. TOTAL PRICE (€) |