New FARO-GOLD® 5-Axis CNC Milling Machine for Rings, Bangles, Engraving, Diamond Cutting, Drilling & Stone Setting

New FARO-GOLD® 5-Axis CNC Milling Machine for Rings, Bangles, Engraving, Diamond Cutting, Drilling & Stone Setting

Location:Pawtucket, RI

or

Call 1-800-619-GOLD

Description

ADVANTAGES OF OUR MACHINES VS. COMPETITION

Faro machine F1

– The base in natural marble granite guarantees the highest stability in time and reduces vibrations

– High working speed

– Ultra speed diamond tool. 200 mm of diamond-cut coil per minute

– Ultra speed satin tool, 200 mm of satin coil per minute

– Guilloche tool for engraving (“such as handmade”)

– Wheel diamond tool with the automatic change of 3 tools

– Possibility to set wheels from 15mm to 63mm of diameter

– Highest flexibility to work on the whole surface of the metal coil ( vacuum plane)

– Coil fixing system to the vacuum plane with pneumatic press for the use of uneven coils

– Automatic alignment systems

– Automatic mapping system of the coil for the working on coils that are not perfect or that have non flat surfaces

– Dedicated CAD-CAM package software, with all the necessary automatic functions for the satin, diamond cutting, laser and engraving work

For the machines with laser:

– Possibility to do marking and cutting both in the combined area (inside the machine) and in the stand-alone area (outside the machine

– Great usable area with single exposition, 180 x 80 mm

– No loss of metal vapors or smoke thanks to the mobile cowl system and special aspirator

Faro machine F35

– Base in natural marble granite

– Toggle switch angle from + 125° to -125°

– 360° continuous and infinite rotation

– 13 tools

– Automatic ring loader

– Automatic probe to work on imperfect or uneven oval objects or with a imprecise shape

– Laser interferometer for the diamond cutting on objects with imprecise shapes

– Automatic tool change for diamond cutting

– High working speed and high precision

– Highly specialized package software CAD-CAM for the creation of cylindrical, bombed, ovals or specially shaped rings and bangles. Easy, quick and intuitive. 2Ddrawings and automatic 6 axes transformation.

MACHINE DESCRIPTION

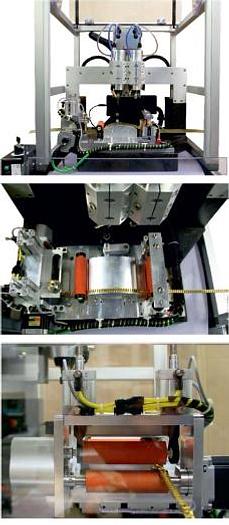

F1isoneofthe

mostefficientandflexibleCNCmilling

machinesworldwide.Itcan carry

out18different

operations,frontandback,onflatsheets.Itshighlyrefinedmechanicsallowsaperfectalignmentofthe

axesgeometryandguaranteessteadinessthanksto the granitein the

basement.Theseparatetractionofthelinearaxesensuressmooth and precisemovements.Itisequippedwithasetofuniqueaccessories,such

asthevectordiamondcutterforthejewelryindustryorthe pivotingblade for

the eyewearindustry.

F35is the all-around,native5-axis

machinethat represents

yearsof

ongoingenhancementscarriedoutbyFAROSRLtorespondtothe

needsof the jewelry manufacturingindustry.Thanks

toits small

footprintandbig versatility,tothe distinctivefeaturesoftheproprietaryPiGreco program and

to the customizableconfiguration,F35is oneofthe

mostpopular

systemsinthe jewelry industryforallengraving,diamond-cutting,drilling

andstonepre-settingtaskson 3Dbanglesandrings.ThestyleF35is a

compactmachiningcentertoprocessweddingrings,rings

andbangles,

designedandmanufacturedbyusincompleteindependencetogether

withawide rangeofaccessories

toconfigurethe systemexactlyaccordingthe specificrequirementsofeverysingleCustomer.

FARO F1

ü Automatic Tube Dragging

ü Automatic Alignment

ü Natural granite structure

ü Look-ahead function

ü Multi-function head

ü FAYb Laser

ü Skipper control software

ü All-in-one CAD/CAM software

FARO F35

ü Diamond Cutting head

ü Natural granite structure

ü Faro Numeric Control

ü Automatic Tool Changer

ü Automatic Ring Loader

ü Pneumatic vice for rings and bangles

ü Skipper NC control software

ü Pigreco is an integrated 7 axis CAD-CAM

Alltheprocessesaremanagedbyhighlyspecializedsoftware

packages,developed

byourownteam ofengineers,withlots ofusefulfeaturesthat, thankstotheir

easeinthe useand rapidity, free the creativityof the operatorand allow the creationof uniqueobjectswith outstandingfinishesand

effectsinjustafew,simple

stepsleavinganywayfullcustomization

freedom.

Engraving,diamond cutting,drilling, stonepre–setting,

grazing,satin

finishing,blipping,profilingand millingareonlyafewofthemachiningprocessesthatcan

beperformedwithourmachines.

designed,developed andrealizedinour

company,weareabletofastandproperly answerany questionaboutthe use,the maintenanceandthemachineoperation.Our equipment

is foreseenwith thelatestsafetysystems, prevention andguaranteeofabsoluteprecision

accordingto the mostdemandingstandards,andis availableinEuropean

andNorthAmericanversions.

600kg/1.300lbs),specificallydesigned toeasilycollectallpreciousmetalschipsinside,

easytobeused,can

fitalsosmalllabs thanks

toitsquiet operationnoise.

high-qualitylinearguidesandball-screws(alsoinstainlesssteel),

high– efficiencybrushless

motors,HFelectrospindlesof1,2÷1,8kWpowerand50.000

or60.000RpMwithrun- out lessthan0,001 mm, automatictool

changeand7-tool

magazine,

CNCcontrolledcoolingsystemto keep

spindleanddiamond–cuttingdeviceataconstanttemperature.

VERSATILE: Despite the small footprint, the F1 has a very large work area of 320 x 450 mm or 12 x 18”, and in the GOLD version features simultaneously the automatic coil dragging system with an area for precise engraving and diamond-cutting on vacuum table and another one for the final cut with automatic pneumatic vise; pneumatic vise forsingle sheet 0,1 ÷ 10 mm thick and up to 100 mm wide and 450 mm long, with removable vacuum table for pre-series and sample preparation; spindle with automatic toolchange. F35 is a native 5-axis machine with wide range of freedom (+ or – 120° tilting axis and endless rotating axis), automatic tool change with 9 or 13 positions

EASY TO BE USED: The system is supplied with a specific software with lots of dedicated features to generate amazing effects and reduce the programming time in the manufacture of samples and production start-up

LOW RUNNING COSTS: Power supply 220V, optimized consumption, low need of compressed air

Faromachine

F5

It’saflying

bridge–

fixbed type

machine

tool with

structurein naturalgranite,stainlesssteeland aluminum,linear axeson

rails with

carriages

on recirculating ball bearingsandleadscrews with recirculatingballbearings,angularaxeswithzero-backlashgear boxes.

Thehigh–resolution

stepperdrivesguarantee

highperformancesandexcellentaccuracycombined

with hugereliabilityandminimumsize.

Inits

standardconfiguration,the F5comeswithelectrospindleofmax25.000 RpMfordiamond-cutting with verticaltool, diamond-cuttingwheelandautomatic

draggingdevice,

andupondemandcan be

equippedwithmechanicalprobetoacquire

the reliefofsemi-finisheditemsortoconvert2Dinto

3Dtool

pathsprojectedonthe

surfacetobemachined.

Thesystemissupplied

with CAD–CAMsoftware suitespecificforjewelry

with

lots

ofusefulfunctionsto easilyandquicklygenerate

newmodelsanduniqueeffects.

DIAMONDHEAD

Thisrevolutionarydevice

isbasedonapivoting

andhi-speedrotating

headwith manual

changingwheel, and

according to the job

specifications,itturnstheF5andinto combinedmilling &

diamond–cutting machines.AspecialFeatureonPigrecoCADcan

driveitinasynchronizedmovementwiththe

otheraxis.

DATA SHEET

Linear Axes Travel: X: 310 mm

Max. Feed Rate

XY : 7.200 mm/min Z: 6.000 mm/min Resolution: 1 μm Accuracy: ±10 μmRepeatability: ±10 μm Numeric Control:

Faro FDC

Processor 64 bit floating point

Multi–function Remote Control Presetting automatico degli utensili Automatic Tool Preset

5 AUX CNC controlled outputs

2 CNC controlled air/water lines

Click-To-See Videos of Machine in Operation:

Priced Upon Request

Specifications

| Condition | New |

| UNIQUE | SincetheMechanics,Electronics,SoftwareandFirmwarearecompletely |

| COMPACT | Smallfootprint(1×1,4×1,8mt/40x55x70”),light(= |

| PRECISE | Baseinnaturalgranite, |

| FAST | Continuousinterpolationupto6axes |

| Y | 190 mm |

| Z | 120 mm |

| 4 Mb RAM Interface | USB |

| Available | Ex-Factory, Italy |