Machinery, Equipment, Tool & Die Needs

Up to 60 Kilobars Per Hour

Up to 240 100g Bars Per Hour

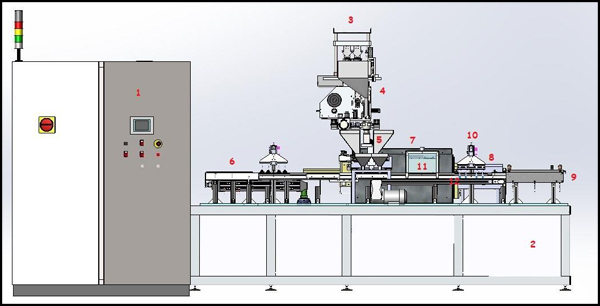

Description of the System:

Automated Filling Station for Graphite Molds:

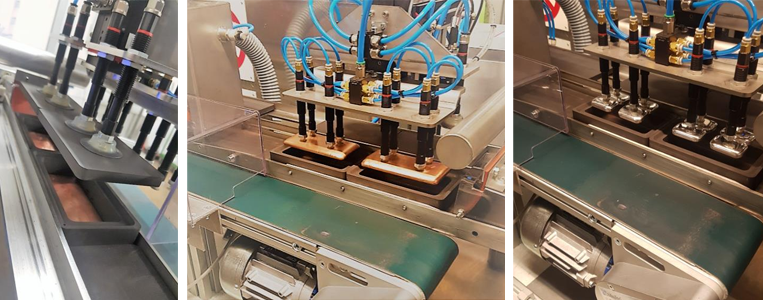

The filling group of the molds and closing lids consists of:

The ingot mold loading station pours the weighed metal from the glasses to the ingot mold.

The empty ingot molds are filled by pouring the glass material into a hopper. The hopper moves to fill the ingot molds correctly.

After filling the ingot molds, a translator arranges to position it above the lid.

Automated Station for Opening Molds

& Unloading Bars:

The molds automatically have their covers removed and the finished bars are lifted and unloaded on to a conveyor belt.

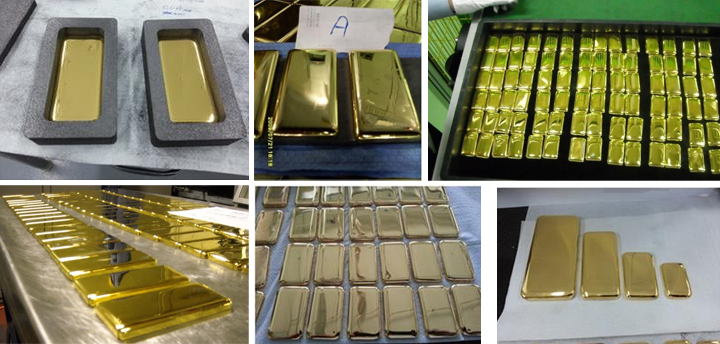

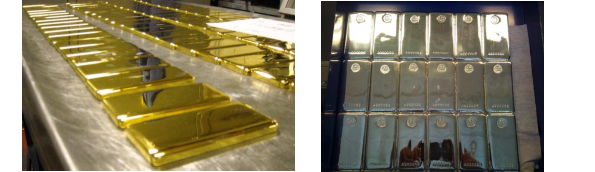

Examples of Finished Bars: